26th June 2023

MONO-BLOC VS. BI-PANEL PARTITION SYSTEMS: WHAT ARE THE DIFFERENCES BETWEEN THEM?

MIDDAS modular partition systems have been engineered for performance and easy installation, and are ideal for any commercial or industrial application requiring a robust, durable wall finish. But when it comes to specifying the best system for your fit out project, how do you know which system to choose?

Mono-bloc partitioning is best suited to applications where cost and longevity are paramount, but where flexibility of the configuration is not the main project driver. MIDDAS M65 mono-bloc is a budget-friendly system, ideal for economical cleanrooms and lower end factory partitioning where panels can be installed, and stay put.

Conversely, bi-panel partitioning is best suited to applications where interchangeability of the configuration and other performance factors such as fire, acoustic and structural ratings are most important. MIDDAS M100 and M200 bi-panel systems are performance engineered for heavy duty installations within the most rigorous environments, such as higher end cleanrooms and high specification commercial offices.

Now, let’s dive into the key features of each system, including the differences between them and some of the common benefits.

What is mono-bloc partitioning?

MIDDAS M65 mono-bloc partitions consist of two steel skins with a bonded paper honeycomb core or optional mineral fibre core for fire rated walls. Mono-bloc is also known as double skin partitioning. The panels are installed progressively by sliding them into a head and floor track. They fit together with a proprietary click-fit connection, with added structural integrity provided by an integral jointing strip. Since there is no channel void with a mono-bloc system, locating services within panels needs to be accounted for during manufacturing with factory-prepared configuration.

With a progressive build, installation is quick and easy. One thing to consider, is that once a panel is installed as part of the wall, it is less easy to remove individual panels. To remove one panel, all panels before it would first need to be slid out. However, with less system materials (i.e., steel framework and panels), a mono-bloc system is often more cost-effective than a bi-panel system, yet is still as robust.

M65 Features & Benefits

Services can be routed through the panels in fixed channels, which are pre-formed in the factory. Optional service penetrations can also be incorporated.

The system is installed in a rapid, progressive build yet remains fully demountable and relocatable.

Head and base track allows for telescopic movement and surface mounted coving and skirting.

Can be installed to a maximum installation height of 4000mm.

What is bi-panel partitioning?

MIDDAS M100 / M200 bi-panel partitions consist of two steel panels, each with a bonded plasterboard backing, that are friction fit onto our primary Heavy Duty structural steel framework (to BS 5234 Part 2 1992). The panels are installed on both sides of the steel frame, leaving a void in between that is ideal for convenient routing of power and data services cabling. The void can also be filled with mineral fibre insulation for enhanced fire rating and acoustic performance. Each panel is hung on the framework individually in a non-progressive build, meaning panels can be put up or taken down one by one. With our bi-panel system, individual panels can also be removed while ceiling and flooring coving is in situ.

Our bi-panel system also comes with integrated options, such as shelving and dado rail. It is capable of services loading up to a force of 2.5kN/m2, with options for a walk-on service deck and integrated edge protection.

M100/M200 Features & Benefits

Services can be routed through the panels and framework as necessary. Configuration does not need to be decided in advance and can change during installation should the need arise. Optional factory-formed service penetrations are also available.

The system is fully demountable and non-progressive, making it easy to remove and reconfigure panels individually as required. This means if your services layout changes unexpectedly, or a single panel sustains damage and needs to be replaced, this can easily be done in situ without removing a whole line of panels, or the ceiling and flooring coving.

Recessed head and base tracks, ideal for flush floor/ceiling coving or for creating shadow gaps.

Can incorporate optional extras, such as integrated shelving and dado rail for small power and data service penetrations.

Can be installed to a maximum height of 6000mm (M100) or 10000mm (M200), in multiple panel lifts.

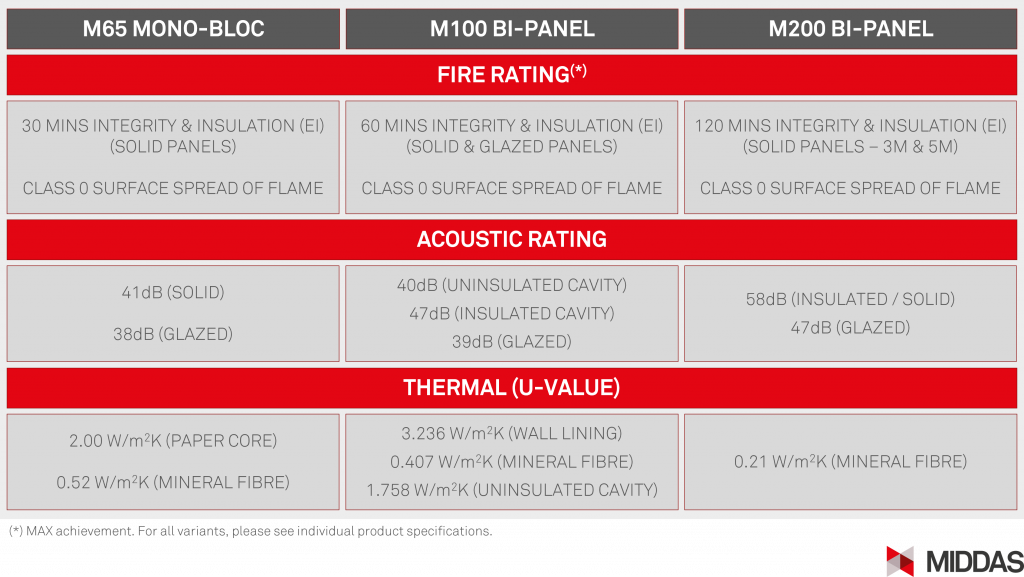

Performance & Specification Differences

Our systems have been independently tested and are backed by rigorous test data. Below is a summary of the performance ratings for fire and acoustics:

Common Features & Benefits

There are also some common features and benefits to both our mono-bloc and bi-panel partition systems.

Designed for integration: Both systems integrate flawlessly with third-party systems to create flush, ledge-free floor, ceiling and door interfaces using our proprietary frame fixings and pre-formed junctions. This offers architects, specifiers and contractors complete flexibility and choice when specifying partition systems for their projects.

Sustainably sourced and recyclable: Both systems are manufactured using sustainable and highly recyclable steel. At end-of-life, bi-panel and mono-bloc structures and all associated framework and can easily be dismantled and recycled, or reconfigured for use elsewhere.

Designed for Manufacturing & Assembly (DfMA): Our design process follows the engineering principle of DfMA to reduce waste during manufacture and optimise production capacity. All panel layouts and structural framework are fully modulated to exact project specifications and are supplied pre-drilled, which eliminates the need for onsite modifications.

Bespoke manufacturing capabilities: Our design flexibility means we can easily accommodate specials and one-off project requirements without disruption for our clients.

Strong performance ratings: Both systems have been rigorously tested as complete systems and carry excellent performance ratings for fire, acoustics, structural integrity and air permeability.

Summary

There are many types of steel partitioning systems on the market, including some this article doesn’t focus on, such as dry lining (plasterboard) or single skin steel systems. When it comes to which type of partition system to specify, make sure you understand the features and benefits, as well as any differences between them. This should help you decide which performance indicators matter most to your project.

MIDDAS mono-bloc and bi-panel partition systems bring efficiency and cost-savings to your project through faster work programming, reduced on-site build time, minimised waste and future proofing with complete system reusability. With a vast client base and extensive experience supplying systems for a variety of commercial interiors applications, including cleanrooms, controlled environments, cGMP and advanced manufacturing, we’re an ideal partner for your next project.

Follow us for industry leading news and insights…

Join our mailing list to receive our regular newsletter!